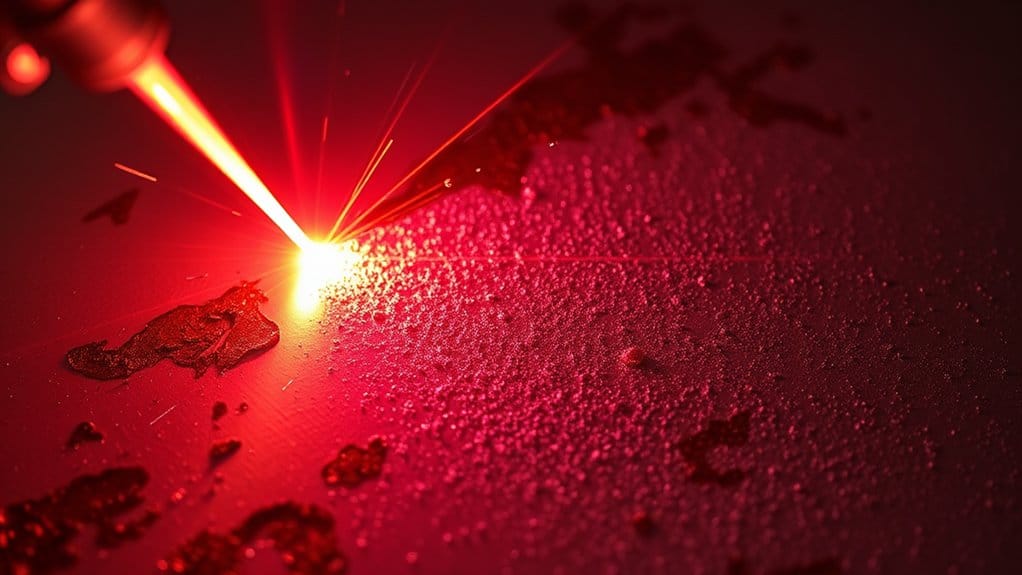

Laser cleaning, as championed by Laser Cleaning Portugal, utilizes short laser pulses to disrupt the molecular bonds within paint layers, leading them to vaporize or sublimate.

This revolutionary process generates shockwaves that effectively remove paint while safeguarding the underlying substrate. Precision calibration is crucial to target specific layers without compromising the base material.

As an environmentally friendly solution, laser cleaning eliminates coatings without the use of harmful chemicals. At Laser Cleaning Portugal, we minimize contamination risks and uphold surface integrity, setting benchmarks for ecological responsibility and safety.

Our partnerships with industry leaders in construction, inspection, and manufacturing, along with collaboration with local educational institutions, ensure we remain at the cutting edge of laser-based technology.

Explore further insights into its applications and future innovations with Laser Cleaning Portugal.

Key Takeaways

- Laser cleaning removes paint by targeting molecular bonds with nanosecond laser pulses, causing the paint to vaporize or sublimate.

- Shockwaves generated by the laser pulses efficiently eject paint without harming the substrate.

- Calibration optimizes laser pulse intensity and duration for effective removal of different paint types and thicknesses.

- Non-contact operation ensures surface integrity is preserved, minimizing wear and tear on underlying materials.

- Efficient extraction systems collect ejected materials, preventing secondary contamination and maintaining a clean environment.

Understanding Laser Ablation

When we investigate the domain of laser ablation, it’s essential to understand how this technology effectively removes paint without harming the substrate beneath. By providing nanosecond laser pulses, laser ablation targets and breaks the molecular bonds in paint layers. This precise energy conversion into heat causes the paint to vaporize or sublimate, shifting directly from solid to gas. During this process, contaminants are ejected and efficiently extracted, minimizing secondary contamination and enhancing safety.

We carefully calibrate laser settings to maximize energy absorption by the paint, ensuring precise control over removal depth. This method is versatile, suitable for numerous surfaces like metals, wood, and concrete, provided they can withstand up to 100°C. This approach grants us freedom from conventional, abrasive methods.

The Role of Shockwaves in Paint Removal

In our exploration of shockwave activity during laser cleaning, let’s examine how these precisely calibrated shockwaves efficiently eject paint while preserving surface integrity. The shockwaves, generated by nanosecond laser pulses, break molecular bonds and facilitate the sublimation of paint, allowing it to convert directly from solid to gas. This energy transfer guarantees contaminants are removed without damaging the substrate, and effective extraction systems capture the resultant debris, maintaining a clean and safe environment.

Shockwave Paint Ejection Mechanics

Understanding the mechanics of shockwave paint ejection reveals the intricate role these shockwaves play in laser cleaning. By employing laser technology, we generate nanosecond laser pulses that produce shockwaves, efficiently ejecting paint from surfaces. These shockwaves create rapid pressure changes, dislodging paint molecules without harming the substrate. The energy absorbed during laser ablation vaporizes paint through sublimation, converting it directly from solid to gas. By calibrating laser settings, we optimize pulse intensity and duration, ensuring shockwave energy precisely breaks the molecular bonds of the paint layer. This controlled approach allows for the safe removal of coatings, including hazardous materials, while preventing secondary contamination. The minimal disruption caused by shockwaves aligns with our pursuit of freedom, offering a precise and efficient cleaning solution.

Surface Integrity Preservation

As we investigate the preservation of surface integrity during laser cleaning, it becomes evident that shockwaves play an essential part in this process. These shockwaves are generated by nanosecond laser pulses, effectively ejecting contaminants or vaporizing paint without harming the substrate layers. The rapid pressure changes from laser ablation create shockwaves that dislodge paint, maintaining the surface’s integrity beneath. Our laser cleaning solutions allow for precise calibration of laser settings, targeting specific paint layers with minimal disruption to surrounding materials. This non-contact coating removal technique retains the original surface texture and quality, minimizing wear and tear. Shockwaves enable selective paint removal, efficiently stripping multiple layers with varying properties without compromising the base material, offering freedom from traditional abrasive methods.

Efficient Energy Transfer

While exploring the role of shockwaves in paint removal, we find that efficient energy transfer is crucial for ideal results. Laser energy, delivered through pulsed beams, generates shockwaves that effectively break molecular bonds within the paint layers. This process causes rapid temperature increases, leading to the sublimation of paint from solid to gas. The shockwaves play a critical role in ejecting contaminants, guaranteeing minimal risk to the substrate beneath. Our coating process benefits from the precise calibration of the laser system, which optimizes energy transfer for varying paint types and thicknesses. In addition, efficient extraction systems are essential, as they safely remove ejected dust and gases, maintaining a clean environment. This guarantees that freedom from unwanted coatings is achieved without compromising underlying materials.

The Importance of Calibration in Laser Cleaning

Calibrating the laser cleaning system is essential for optimizing paint removal effectiveness while protecting the substrate beneath. By fine-tuning the energy output and pulse duration, our calibration guarantees laser systems operate with precision. This adjustment is fundamental for matching the laser parameters to the specific type and thickness of paint, maximizing cleaning efficiency without substrate damage. Regular calibration assures consistent performance, reducing variability in paint removal depth and guaranteeing reproducibility across sessions. We also assess surface reflectivity and material compatibility, which is critical for tackling diverse paint colors and substrates. Properly calibrated laser systems control the dispersion of paint particles and gases during ablation, markedly minimizing secondary contamination. This careful calibration process enables us, granting the freedom to achieve precise and clean results.

Safety and Environmental Benefits

Let’s investigate how laser cleaning offers significant safety and environmental benefits through its non-toxic paint removal process. By eliminating the use of harmful chemicals and minimizing waste generation, we effectively reduce the environmental impact and potential contamination. Additionally, laser ablation guarantees a safer work environment by preventing the release of hazardous particles, making it a preferred method for personnel safety.

Non-Toxic Paint Removal

Understanding the safety and environmental benefits of laser cleaning for non-toxic paint removal is essential for industries prioritizing eco-friendly practices. Laser paint removal stands out as an environmentally friendly option due to its precision and efficiency. This technology uses laser ablation to eliminate hazardous paints like those containing lead or chromate, without releasing toxic particles. It guarantees safety and minimizes secondary contamination risks, especially in sensitive environments such as aerospace and military sectors. Key advantages include:

- No chemical agents or blasting materials needed, reducing waste and pollution.

- Efficient suction systems collect removed materials, preventing their dispersal.

- **Controlled process mitigates *health risks***, avoiding exposure to toxins.

- Precise application reduces environmental footprint, aligning with sustainable practices.

This method offers industries the freedom to remove paint safely and responsibly.

Minimal Environmental Impact

By utilizing laser paint removal, we greatly reduce environmental impact due to its non-contact method that eliminates the need for harsh chemicals or blasting agents. This innovative approach generates minimal waste by directly vaporizing paint into gas, thereby ensuring no secondary contaminants enter our environment. Laser cleaning is an environmentally conscious choice, producing no harmful byproducts, and it’s even endorsed by the US Air Force for its eco-friendly attributes. Additionally, the process minimizes the risk of exposure to toxic materials like lead and chromate, which are prevalent in hazardous paints. This efficiency not only enhances safety but also markedly reduces the energy consumption compared to traditional methods, ultimately contributing to a lower carbon footprint and supporting our pursuit of ecological freedom.

Safe for Personnel

While laser cleaning‘s minimal environmental impact sets a new standard in ecological responsibility, its benefits extend considerably to personnel safety. The process is inherently safe for personnel, as it operates without contact, thereby reducing injury risks linked to traditional mechanical methods. By precisely targeting paint without damaging the underlying substrate, it prevents damage-related accidents and guarantees a safer working environment. Significantly, the US Air Force’s endorsement emphasizes its compliance with rigorous safety standards.

Key safety advantages include:

- Non-contact operation: Minimizes physical injury risk.

- **No *hazardous chemicals***: Eliminates exposure to toxic substances.

- Controlled dust and gas extraction: Reduces secondary contamination.

- Substrate integrity: Guarantees only the paint is removed, leaving the substrate unharmed.

These points highlight laser cleaning’s role in promoting a safer, more responsible industrial environment.

Applications in the Aerospace Industry

In the aerospace industry, laser cleaning stands out as an essential technology for safely removing hazardous coatings, such as hexavalent chromium, commonly used in aircraft manufacturing. Coatings need precise removal to guarantee the integrity of critical components. The US Air Force’s approval of laser ablation highlights its effectiveness in maintaining substrate integrity while eliminating toxic particles. Our focus on laser cleaning minimizes secondary contamination, offering a safer alternative to traditional methods. Its precision is unmatched, allowing us to target complex areas like weld seams without compromising performance. Furthermore, integrating automated laser systems into production lines enhances efficiency and consistency in maintenance processes, liberating us from the constraints of manual techniques while guaranteeing the highest safety standards in aerospace applications.

Applications in the Automotive Industry

Having investigated the essential role of laser cleaning in the aerospace industry, we now examine its significant influence on the automotive sector. Laser cleaning is priceless here, removing hazardous coatings like hexavalent chromium while preserving substrate integrity. This technology amplifies efficiency, streamlining production by reducing setup and teardown times compared to traditional methods. The precision of laser cleaning guarantees selective stripping of coatings without damaging the metal underneath, leading to reduced scrap rates. Additionally, it enhances electrical conductivity in automotive parts, imperative for electric and hybrid vehicles. Automated systems integrate seamlessly into factory workflows, providing consistent, high-volume paint removal. Key advantages include:

- Enhanced safety with hazardous coating removal

- Increased manufacturing efficiency

- Precision in maintaining metal surfaces

- Improved electrical conductivity for modern vehicles

Challenges With Reflective Paints

Encountering reflective paints in laser cleaning presents a unique set of challenges that often demand a sophisticated approach. Reflective white paints tend to bounce back laser beams, leading to longer cleaning times and reduced effectiveness. This reflection means less energy is absorbed, making it hard for the laser to generate necessary heat for effective ablation. To overcome these obstacles, we might need to adjust laser settings, such as increasing power or extending exposure times, ensuring coatings without excessive reflection issues. Specialized laser wavelengths or beam shaping techniques can be employed to enhance interaction with reflective surfaces, improving efficiency. Additionally, extra monitoring and extraction systems are essential for safely managing ejected particles during the process, ensuring a clean and controlled operation.

The Precision and Efficiency of Laser Technology

Reflective paints challenge us to adapt our laser cleaning strategies, but the precision and efficiency of laser technology offer a strong solution. By leveraging micron precision, we can selectively remove paint layers without harming underlying surfaces. The laser ablation process effectively breaks molecular bonds, causing paint to sublimate, converting directly into gas. This method allows us to handle various coatings, including hazardous ones, efficiently.

Key advantages include:

- Non-contact nature: Minimizes wear and tear, reducing damage risks.

- Adjustable settings: Tailor laser parameters to different material properties.

- Immediate extraction: Guarantees a clean workspace, preventing secondary contamination.

- Waste reduction: Eliminates harmful waste, promoting safety and environmental care.

These factors make laser cleaning a superior choice, combining precision with eco-friendly efficiency.

Industry-Specific Use Cases

Let’s examine how laser cleaning addresses industry-specific challenges, particularly in aerospace and automotive sectors. In aerospace, laser technology effectively removes hazardous coatings like hexavalent chromium, safeguarding both worker safety and compliance with stringent environmental regulations. Meanwhile, automotive manufacturers benefit from laser paint stripping solutions that enhance production efficiency while preserving substrate integrity, streamlining processes considerably.

Aerospace Hazardous Coatings Removal

When it comes to removing hazardous coatings in the aerospace industry, laser cleaning offers a state-of-the-art solution that meets both safety and efficiency requirements. Laser paint removal is especially effective for eradicating coatings like hexavalent chromium without harming the underlying substrate. This guarantees compliance with strict safety regulations. The US Air Force recognizes laser ablation technology for safely removing toxic materials, reducing airborne contaminants. By using laser technology, we can address multiple coating layers, achieving a pristine surface ready for repainting, which is vital for maintaining aircraft integrity.

Key benefits include:

- Minimal waste generation

- Environmentally friendly process

- Preserved structural integrity

- Compliance with safety standards

Ultimately, this innovative approach grants us the freedom to enhance safety while adhering to environmental standards.

Automotive Paint Stripping Solutions

While laser cleaning technology revolutionizes the aerospace industry, it’s also reshaping automotive paint stripping solutions with its precision and efficiency. In the automotive sector, this technology adeptly removes paint layers such as e-coating, powder coating, and cataphoretic paint, ensuring surfaces are primed for ideal welding and bonding. By selectively targeting paint layers, laser cleaning prevents contamination of surrounding components, preserving the integrity of sensitive parts like electrical connectors. Additionally, it eliminates hazardous coatings, including hexavalent chromium, without compromising the underlying metal, thereby enhancing safety and regulatory compliance. Integrating high-power laser systems into production lines streamlines paint removal, reducing downtime and scrap rates. This non-contact method minimizes wear, offering a refined, efficient approach to high-volume automotive manufacturing.

Future Innovations in Laser Paint Removal

As we look to the future of laser paint removal, it’s essential to focus on innovations that enhance system efficiency and adaptability. Our exploration into laser technology promises to eclipse traditional cleaning methods with advancements like AI and machine learning, enabling real-time system adjustments based on surface conditions and paint types. Researchers are also developing multi-wavelength laser systems to target diverse paint materials, increasing versatility and reducing processing times.

Key future directions include:

- Robotic automation: Streamlining integration in industrial settings for precision.

- Eco-friendly solutions: Minimizing waste and improving energy efficiency.

- Higher power outputs: Allowing removal of thicker coatings with minimal damage.

- Refined pulsing techniques: Facilitating the handling of more complex paint systems.

These innovations will offer us the freedom to exceed current capabilities.

Conclusion

At Laser Cleaning Portugal, we are pioneering sustainable cleaning solutions by efficiently removing paint using laser ablation and shockwave interactions. Much like a skilled artist with a precise brush, our advanced laser technology ensures accurate calibration for safe and environmentally friendly applications. This innovative approach has significant implications across various industries, including aerospace, where precision is paramount.

Our commitment to staying at the forefront of laser-based technology is reinforced through our partnerships with industry leaders in construction, inspection, and manufacturing. By collaborating with local educational institutions, Laser Cleaning Portugal ensures that we provide unmatched services throughout the country. While challenges with reflective paints remain, the precision of our technology offers promising, industry-specific solutions.

Looking to the future, Laser Cleaning Portugal is dedicated to refining and expanding the capabilities of laser paint removal, ensuring that our services continue to lead the way in sustainable and efficient cleaning solutions.