Advanced Technology

We use state-of-the-art laser systems to achieve outstanding cleaning results.

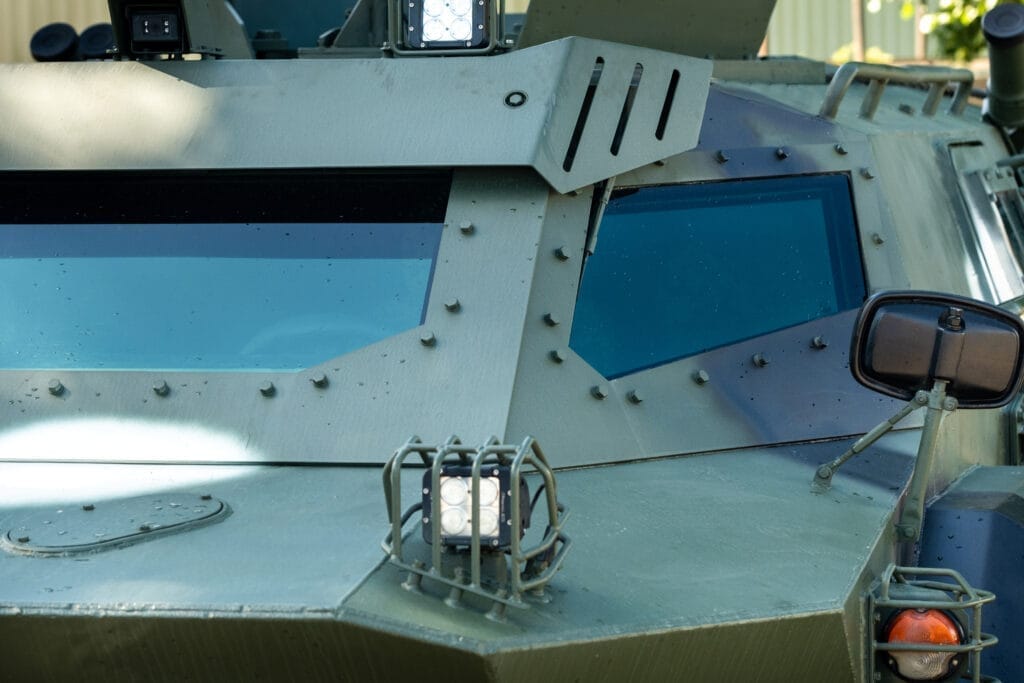

Many might not realize that laser cleaning is quickly becoming a game changer in the defence and military sectors, offering not just efficiency but also environmental benefits. This technology allows us to maintain equipment with precision while eliminating harmful chemicals from the process.

Customers Served

Jobs Done

Review Rating

One of the standout advantages of laser cleaning is its ability to drastically reduce equipment maintenance time. By streamlining depaint processes, we enhance operational readiness, allowing military units to focus on their core missions rather than prolonged maintenance tasks. This method promotes cost efficiency and minimizes the use of harmful chemicals, thereby improving worker safety.

With reduced reliance on personal protective equipment (PPE), we create a safer work environment for our personnel. Moreover, the technology’s reliability guarantees that we can depend on consistent performance, reducing unexpected downtimes associated with traditional cleaning methods.

Laser cleaning achieves unparalleled cleaning precision, preserving the integrity of sensitive components without altering their shape. This preservation enhances the durability and functionality of critical military assets, which is essential in high-stakes environments.

In addition to maintenance reduction, the environmentally friendly nature of laser cleaning supports sustainability initiatives within military operations. By producing no hazardous waste, we align our practices with modern environmental standards.

Laser cleaning provides a precise and controlled method for removing various coatings, from paint to industrial protective layers, without damaging the underlying substrate, offering superior selectivity and efficiency compared to traditional methods.

The laser cleaning process effectively removes rust and oxidation while simultaneously creating a micro-textured surface that enhances corrosion resistance, making it an ideal solution for both corrosion removal and prevention in industrial applications.

When dealing with hazardous materials like lead-based paint, laser cleaning offers a contactless, dust-free removal process that contains and captures harmful substances without generating secondary waste, ensuring worker safety and environmental compliance.

Laser cleaning achieves an exceptionally clean and properly textured surface that optimizes adhesion and weld quality, eliminating contaminants and oxides that could compromise joint integrity, while providing consistent and repeatable results for critical bonding applications.

Quality, Precision and Eco Friendly

When you choose Laser Cleaning Portugal, you’re opting for quality, precision, and a commitment to the environment. Here’s what makes us stand out

We use state-of-the-art laser systems to achieve outstanding cleaning results.

Our team consists of trained experts dedicated to delivering top-notch service.

We prioritize sustainability, using methods that produce no waste or harmful byproducts.

No one likes paying too much. That's why our pricing offers excellent value, making high-quality cleaning accessible to everyone.

Testemonials

Good communication and quick and efficient services are what we strive for. Read what our clients say about Laser Cleaning Portugal

Laser cleaning technology has become an essential asset in the defence and military sectors, offering diverse applications that enhance both efficiency and safety. With laser technology advancements, we can now achieve precision cleaning that notably improves surface preparation techniques. This method is particularly effective for coating removal, drastically reducing the time and costs associated with traditional depaint processes.

As we adopt these cost-saving innovations, we see marked maintenance efficiency improvements, reducing downtime for essential maintenance tasks. This translates directly into operational readiness enhancement, enabling our forces to maintain a high level of preparedness for any mission.

The applications of laser cleaning in welding and bonding processes also guarantee surfaces are contaminant-free, resulting in stronger, more reliable joints. Overall, laser cleaning technology isn’t just a cleaning solution; it’s a strategic tool that supports the military’s operational capabilities.

Our lasers can be adjusted to achieve any desired surface finish, ensuring your assets remain undamaged.

Laser cleaning is a chemical-free and media-free process, eliminating the need for disposal of waste materials after use.

Our laser cleaners are highly portable and can be operated from work platforms, scaffolds, and in confined spaces.

Our service is customized to meet the requirements of the project, providing accurate treatment to only the targeted area.

Our laser cleaners offer immediate results without any waiting time, all at an affordable price for low cleaning laser services.

We can perform cleaning tasks to meet specific predetermined objectives upon request.

In the domain of military and defence operations, the application of laser cleaning technology is altering maintenance protocols. One of the primary applications is coating removal, where lasers efficiently strip away old finishes, ensuring that equipment maintains its ideal performance without relying on harsh chemicals. This capability is essential in tasks such as paint stripping, where traditional methods often pose risks to both the substrate and personnel.

Additionally, laser cleaning plays an important part in nuclear decontamination, offering a safe and effective means of removing radioactive contaminants from sensitive surfaces. This technology enhances corrosion control initiatives, as it mitigates rust and degradation, thereby extending the lifespan of critical military assets.

Moreover, laser cleaning is integral to surface preparation, especially for welding and bonding treatments. By providing a clean substrate, it enhances joint integrity and overall operational reliability.

Quality Service with Precision

We provide a wide range of services related to laser cleaning. We offer eco-friendly cleaning alternatives for a wide range of industries and consumers.

Through the adoption of laser cleaning technology, the military markedly reduces its environmental impact while enhancing operational efficiency. This sustainable technology eliminates the need for harmful chemical solvents and abrasive materials, greatly contributing to pollution reduction. By shifting to laser cleaning, we minimize waste generation; the process produces minimal debris compared to traditional methods like sandblasting.

Moreover, the eco-friendly nature of laser cleaning promotes worker safety. With reduced exposure to toxic substances, military personnel require less personal protective equipment (PPE), creating a healthier work environment. This change supports compliance with safety regulations and enhances overall morale within the workforce.

Energy efficiency is another key advantage of laser cleaning. By utilizing advanced laser systems, we lower the carbon footprint associated with equipment maintenance greatly. This aligns with our sustainability goals and reflects our commitment to environmentally responsible practices.

At Lasercleaning.pt, we are dedicated to promoting these environmentally friendly practices in the Defence & Military sector, ensuring that the industry moves toward a more sustainable future.

At Laser Cleaning Portugal, we are committed to providing eco-friendly and efficient laser cleaning solutions. As on of the few certified provider in Portugal, we use advanced technology to deliver exceptional results for both individuals and businesses. Our services cover a wide range of needs, from roof and mould cleaning to paint and rust removal, ensuring a cleaner, safer environment for all.

Customers Served

Jobs done

Review Rating

Choose Laser Cleaning Portugal for reliable and sustainable cleaning solutions tailored to your needs. Contact us now to learn how we can enhance your environment with our certified services.